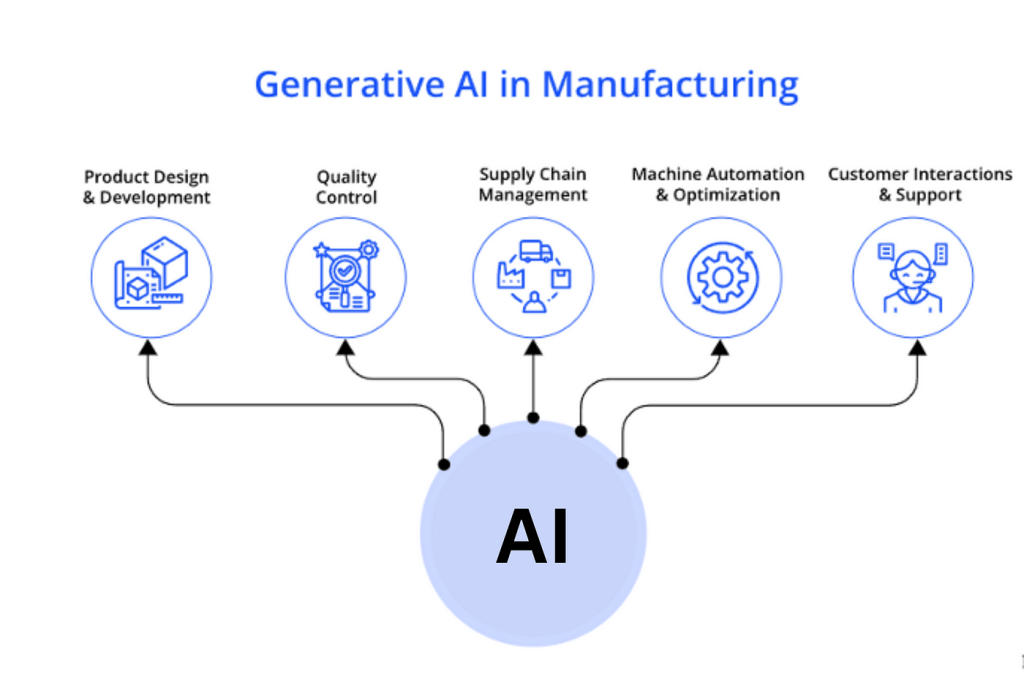

In the dynamic landscape of manufacturing, the adoption of cutting-edge technologies is imperative for maintaining a competitive edge. Among these technologies, generative artificial intelligence (AI) has emerged as a transformative force. This article explores the profound impact of enterprise generative AI solution for manufacturing, shedding light on their benefits, applications, and future potential.

The Evolution of Manufacturing with Generative AI

Understanding Generative AI

Generative AI refers to a subset of artificial intelligence that uses machine learning algorithms to create new data, designs, and solutions based on input data and predefined parameters. Unlike traditional AI that analyzes data and makes decisions, generative AI can generate new outputs, making it particularly valuable in innovative and design-intensive industries such as manufacturing.

Historical Context

Historically, manufacturing has relied on human expertise and manual processes for design, production, and quality control. However, the advent of AI and machine learning has ushered in a new era where intelligent systems can analyze vast amounts of data, identify patterns, and make data-driven decisions. Generative AI takes this a step further by not only analyzing but also creating new designs and optimizing processes.

Benefits of Enterprise Generative AI Solution for Manufacturing

1. Enhanced Product Design and Innovation

Accelerated Design Cycles

Generative AI solution for manufacturing significantly reduces the time required for product design by automating the creation of design alternatives. This allows engineers to explore a wider range of design possibilities quickly and efficiently, leading to faster innovation cycles and reduced time-to-market.

Improved Design Quality

By analyzing historical design data and performance metrics, generative AI can suggest optimal design parameters that enhance product quality and performance. This results in products that are not only innovative but also meet higher standards of reliability and efficiency.

2. Optimized Production Processes

Process Automation and Efficiency

Generative AI can automate various aspects of the manufacturing process, from material selection to production scheduling. This automation leads to increased operational efficiency, reduced waste, and lower production costs.

Predictive Maintenance

Generative AI enables predictive maintenance by analyzing sensor data from manufacturing equipment. It can predict potential equipment failures before they occur, allowing for timely maintenance and reducing downtime.

3. Enhanced Quality Control

Real-Time Defect Detection

Generative AI systems equipped with computer vision can detect defects in real-time during the production process. This immediate feedback loop ensures that defective products are identified and rectified promptly, maintaining high-quality standards.

Continuous Improvement

By continuously analyzing production data, generative AI can identify areas for improvement and suggest optimizations. This leads to a culture of continuous improvement, where processes are constantly refined for better outcomes.

Real-World Applications of Generative AI in Manufacturing

1. Automotive Industry

Customization and Personalization

Generative AI enables automotive manufacturers to offer customized and personalized vehicle designs to customers. By analyzing customer preferences and design constraints, AI can generate unique design options tailored to individual tastes.

Autonomous Manufacturing

In the realm of autonomous manufacturing, generative AI plays a crucial role in optimizing the production of autonomous vehicles. It helps in designing complex components, optimizing production processes, and ensuring the quality of autonomous systems.

2. Aerospace Industry

Lightweight Material Design

Generative AI is instrumental in designing lightweight yet strong materials for aerospace applications. By optimizing the material composition and structural design, AI helps reduce the weight of aerospace components, leading to more fuel-efficient aircraft.

Safety and Compliance

Aerospace manufacturers leverage generative AI to ensure that all components meet stringent safety and compliance standards. AI-driven quality control systems detect anomalies and ensure that only the highest quality parts are used in aircraft production.

3. Consumer Electronics

Rapid Prototyping

In the fast-paced world of consumer electronics, generative AI accelerates the prototyping phase by generating multiple design iterations quickly. This enables companies to test and refine their products rapidly, staying ahead of market trends.

Supply Chain Optimization

Generative AI solution for manufacturing optimizes supply chain operations by predicting demand, managing inventory, and ensuring timely delivery of components. This leads to cost savings and improved customer satisfaction.

Challenges and Considerations

1. Data Quality and Availability

Importance of High-Quality Data

The effectiveness of generative AI solution for manufacturing heavily depends on the quality and availability of data. Manufacturers must ensure that they have access to comprehensive, high-quality datasets for training AI models.

Data Security and Privacy

As generative AI systems handle sensitive production data, ensuring data security and privacy is paramount. Manufacturers need to implement robust security measures to protect their data assets.

2. Integration with Existing Systems

Compatibility with Legacy Systems

Integrating generative AI solutions with existing manufacturing systems can be challenging, especially if the legacy systems are outdated. Manufacturers must carefully plan the integration process to ensure seamless operation.

Change Management

Adopting generative AI requires a shift in organizational culture and processes. Manufacturers must invest in change management strategies to ensure that employees are trained and prepared for the transition.

3. Scalability and Flexibility

Scalability of AI Solutions

Generative AI solutions must be scalable to handle varying production volumes and complexities. Manufacturers need to ensure that their AI infrastructure can scale efficiently as production demands increase.

Flexibility in Application

The flexibility of generative AI solutions is crucial for adapting to different manufacturing scenarios. AI systems should be designed to handle diverse applications, from small-scale customization to large-scale production.

Future Outlook

1. Advancements in AI Technology

Improved Algorithms

Ongoing advancements in AI algorithms will enhance the capabilities of generative AI solutions. Improved algorithms will lead to more accurate predictions, better optimization, and enhanced decision-making in manufacturing.

Integration of IoT and AI

The integration of the Internet of Things (IoT) with generative AI will create a connected ecosystem where AI-driven insights are derived from real-time sensor data. This will further enhance the efficiency and effectiveness of manufacturing operations.

2. Increased Adoption Across Industries

Expansion into New Sectors

As generative AI solutions continue to demonstrate their value, more industries will adopt these technologies. Sectors such as pharmaceuticals, energy, and construction are likely to see increased adoption of generative AI for various applications.

Collaboration and Innovation

Collaboration between AI technology providers, manufacturers, and research institutions will drive innovation and the development of new AI-driven manufacturing solutions. This collaborative approach will lead to the creation of more advanced and tailored AI applications.

Conclusion

The impact of enterprise generative AI solutions on manufacturing is profound and far-reaching. From enhancing product design and optimizing production processes to improving quality control and driving innovation, generative AI is transforming the manufacturing landscape. While challenges remain, the future holds immense potential for further advancements and broader adoption of generative AI technologies. By embracing these solutions, manufacturers can achieve new levels of efficiency, innovation, and competitiveness in an increasingly dynamic market.